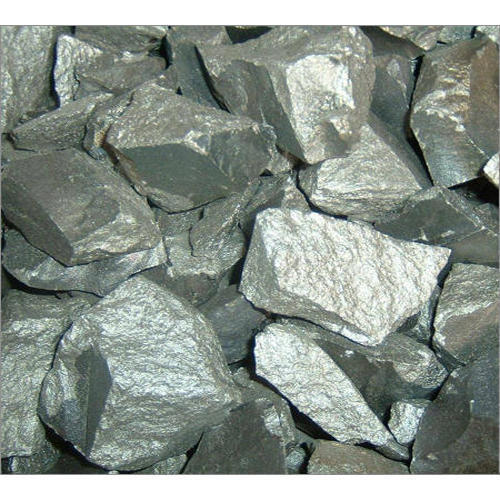

Ferro Silicon

Product Details:

X

Product Description

Ferro Silicon is made up of alloy of silicon and iron comprising average silicon ranging between 15 and 90 percent. Iron silicides have high percentage of Ferro Silicon. Production of our range is carried out by reduction of sand/silica along with the coke while scrap iron, millscale and silicon content near about 15% are present in it. Ferro Silicon we provide found vast application in blast furnaces that have acid fire bricks.Features

- Ferro Silicon is used in electric arc furnaces and have high silicon content

- It is a good silicon source and used for reducing the metals from oxides

- Formulations in which we make our range available are 15%, 45%, 75%, and 90% silicon

- Used in electrode coating and arc welding

- Used in manufacturing of ferrosilicon, cast iron and finds application in iron's inoculation in order to speed-up graphitization

- Prevents carbon loss from molten steel

- Used for deoxidizing of steel and other ferrous alloys

- Used in silicon manufacturing, corrosion-resistant and high-temperature resistant ferrous silicon alloys and silicon

- steel which is used for electromotor and transformer cores.

Enter Buying Requirement Details

Other Products in 'Ferro Alloys' category

|

PAROLIYA MINERALS & FERRO ALLOYS

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |

Send Inquiry

Send Inquiry Send SMS

Send SMS